Welcome to the FAQ area

- What is substrate?

-

Substrate (Lat. substratum = base) is, in the horticultural sense, a substance that is located under the aboveground plant parts. It serves as a location for the plants and supplies them with nutrients, water and air (oxygen).

- How do I find the optimal substrate for my individual application purpose?

-

Content follows!

- My substrate is very dry and poorly takes up water, what can I do?

-

If peat or peat-based substrates dry out very strongly, it can be that they poorly take up water after watering. Stable drops or small puddles form on the substrate and the water pearls up. The substrate behaves hydrophobically, meaning that it "avoids water". Fine substrates, used for propagation, are more affected than coarse structures. terracult substrates contain a special wetting agent and are supplied with a certain moisture content before packaging in order to avoid this effect. It can nevertheless come to exceptions, such as the dry conditions described above.

To make the substrate water receptive again, a wetting agent should be added when watering, according to the application recommendations. There is an advantage of using warm water with a temperature between 20°C and 30°C. Another possibility is the contribution of a certain amount of water before processing sacks or big bales that are still closed.

- A layer of mold has formed on the surface of my substrate, what can I do?

-

The cause is the saprophytically living fungus Peziza ostracoderma. This fungus does not damage garden crops; however, it is a visual problem. In extreme cases, the oxygen supply of the roots can be hindered. The fungus proliferates via spores which are spread easily by wind or during watering. The spores generally die by themselves after a short time.

Getting rid of the mold is quite simple and effective: Water with Dithane Ultra, 0.2 to 0.1 %. The application can cause a light coating on the leaves; we recommend a short watering with clear water afterwards. We are not aware of any plant damages that can occur at the mentioned concentration. Furthermore, the following preparations as fungicides are known: Polyram Combi, Euparen WG, Ortiva. We have, however, no empirical values for these.

- Which relevance does lime have in terracult substrate?

-

The lime or calcium carbonate in the substrate serves the adjustment of the pH suitable for plants, which allows all nutrient elements to be optimally available if possible. In general, this lies between 6.0-6.8 (H2O) or 5.5-6.3 (CaCl2). The acid loving bog plants are an exception. Finely ground carbonated lime is mainly used for substrates. Dolomitic lime contains additional, valuable magnesium.

- What are wetting agents and which function do they fulfill?

-

Wetting agents are ionic or anionic surfactants which increase the surface tension of water. Since peat and peat-based substrates react water-repellently as of a certain drying degree, a wetting agent, that is not harmful to plants, can be added to the substrate. In general, it is a mixture of ionic and non-ionic surfactants which decompose biologically during the course of cultivation.

- Which pH do terracult’s peat and substrates have and how are these measured?

-

You can find an overview of the pH values for terracult’s peat and substrates here. In principle, one can say that the pH for pure white peat from a high moor is around 3 – 3.5 (measured in CaCl2). The pH of black peat lies between 4.0 – 4.5.

For substrates, the pH can be increased by adding an exact amount of calcium carbonate. In our experience, a pH of 5.5 – 6.5 offers most plants the best conditions, that is, this range is also favorable for the absorption of important micronutrients.

- How does the pH have an effect on the growth of plants?

-

In principle, the pH of the soil influences the availability of the nutrients. A pH of 5.5 – 6.5 is recommended for peat substrates. Lower or higher pH values can lead to nutrient regulations. The pH can change due to acidic or basic fertilizer or water containing calcium carbonate during the course of cultivation.

Aluminum or manganese ions get soluble at a low pH. Al ions play an important role in the blue tint of hydrangeas.

- Under which influences in the soil/substrate does the pH value increase?

-

The main cause for the pH to increase is the carbonate hardness found in hard water. Fertilizers with a high amount of nitrate nitrogen (NO³) can also increase the pH.

- Under which influences in the soil/substrate does the pH value decrease?

-

A low carbonate hardness or soft water leads to a decreasing pH value in connection with ammonium containing nutrient salts. In the extreme case, the pH can be reduced during cultivation by adding sulfur. Recommendation: Water with approximately 2 - 3 ‰ net sulfur (not on leaves). Check pH after every treatment.

- What does "soil buffering" mean?

-

Soil buffering is the ability of the soil to stop nutrient or pH changes by absorption. For soils, it is the capability of absorbing nutrients and also releasing them (cation exchange capacity). Humic acids and clay minerals have good buffer qualities.

- What does the salt content in soils mean?

-

The salt content is the sum of all the negative and positive ions in the soil. Salts are chemical connections built up from ions which are not acids, bases or oxides. When soils have a too high salt concentration, the absorption of water becomes more difficult, and at certain concentrations, water actually withdrawals from the plant (plasmolysis). Plants react differently to salt concentrations. Salt-sensitive plants such as Adiantum, Azalea, Erica, Rhododendron and Primula tolerate less than 1 g salt/L substrate. Plants that are insensitive to salt such as Pelargonium, Cyclamen, Euphorbia, Hydrangea, Chrysanthemum and basil tolerate up to 2.5 g salt/L substrate; The salt content is mostly measured as conductivity (EC value) and converted with one factor.

- What is grain size distribution and how is this determined?

-

Grain size and grain size distribution have substantial influence on the structure and the quality of a substrate. A highly fine structure means less air capacity and the material tends to compress. The methodology for regulating the grain size distribution for peat (and substrates) is still based on the DIN standard 11540, item 5.9. The required parameters for sieving are described as well as the calculation and representation of the data.

- Which moisture content do the products have?

-

Peat substrates are delivered relatively dry in order to keep the transport costs low, especially for long distances. Dry goods are also less sensitive towards biological conversion, nutrient and pH adjustments. The moisture content is approximately 45-65 % at the time of delivery depending on the composition and mixture.

- How can peat self-heat and how can that be prevented?

-

The self-heating of peat can happen when the sods are still piled in the field. It is caused by a rising temperature in the material, independent of the outside temperature. It has to do with microbially induced biochemical events.

The danger of self-heating exists when the piled up peat has different degrees of wetness and this increases when the large piles have weighted pressure. The danger gets bigger the warmer the peat is at the time of storage. Therefore on hot harvest days the "harvests" takes place only in the evening hours, which means the peat is brought to the pile later in the day. One recognizes self-heating by the smell of "soup seasoning". Self-heated peat tends to mold and have a higher pH. In general, self-heated peat is not suitable for making substrate.

- What are additives and why are they significant?

-

We distinguish between mineral and organic additives and here are the most important ones: Perlite, clay, expanded clay, pumice (Italy), coco fiber and compost among others.

Depending on their characteristics, they fulfill different tasks. For example, perlite, vermiculite or pumice are used for structural enhancement and to improve the air and water holding capacity (capillarity). Clay minerals (three-layer clay minerals) store nutrients particularly well. Coco fibers improve the water supply. Green waste is used mainly for organic and peat reduced soils. Styro waste, fibrous wood materials, rice husks, and flax shives play only a subordinate role.

- Which relevance and characteristics does clay have as an additive in terracult substrate?

-

Clay helps plants store and release nutrients in accordance with their requirements during cultivation. In general, clay also improves the absorption of water and its distribution. It should not be too fine as it otherwise can be washed out and it can clog the pores up in the lower pot area. This then can lead to waterlogging.

An important quality criterion for clay is the lime concentration which should be as near to zero as possible. Otherwise, the slow release of lime can lead to an unintentional increase in pH during the course of cultivation.

- What is bentonite?

-

Bentonite is a high quality, natural clay mineral that, when used as an additive to substrates, improves the nutrient storage capacity, the swelling volume and the water holding capacity.

- Which relevance and characteristics does perlite have as an additive in terracult substrate?

-

Perlite is a volcanic mineral (aluminum silicate) that foams when heated to approx. 1000°C. Adding 10-20 % perlite to the substrate increases the air pore volume. The sorption and buffering characteristics of perlite are very low.

- What is a moor?

-

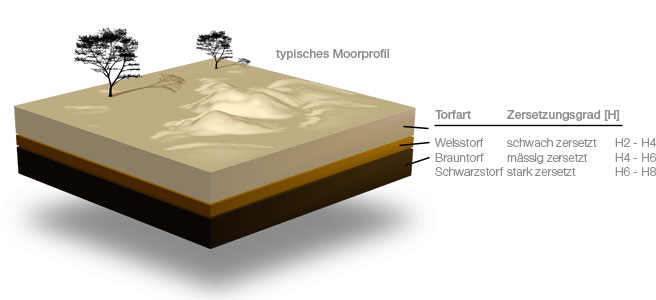

A moor is described geologically and pedologically as an area with at least a 30 cm layer of peat. There are three main bog types: Low moors, transition bogs and high moors.

Low moors are connected to groundwater; they have a large number of species and are mostly rich in nutrients. Low moors formed from the drying up of water bodies. High moors arise in areas with high precipitations and low evaporation and they are not connected to groundwater. They do not have many species and are not rich in nutrients.

High moor peat is by far the most important raw material in commercial horticulture because of its many favorable qualities for substrates. Over 40 million m³ of peat worldwide is processed for gardening substrates and potting soils each year. Both the harvesting method and further processing have a particularly strong influence on the quality of the peat.

- What is peat?

-

Peat is an organic, sedentary deposit (growing from bottom to top) that consists predominantly of dead, humified plant material. This plant material has not yet decomposed completely due to a lack of oxygen caused by water repletion and therefore the structure is at least partly still recognizable.

It is mainly distinguished between white and black peat. The botanical structure of the peat forming plants can still be recognized well in light yellowish brown to dark brown-colored white peat. Black peat is decomposed more strongly than white peat. The most important plants for bog formation are sphagnum moss (Sphagnum spp.) and cotton grass (Eriophorum vaginatum) which makes up the fibers in the peat. Brown/black-colored black peat consists of the plant structure being largely decomposed. There are also transition bogs that blend in the ecological conditions of the high and low moors.

Peat can be compared with a sponge in its structure; it is not very firm and has a high pore volume. Despite a high water holding capacity due to the middle and fine pores, a high air capacity is also given by the large share of coarse pores. With increasing decomposition, the cavity volume (the pore share) decreases and the amount of firm substance (the bulk density) increases. The water holding capacity rises simultaneously and the air capacity gets lower. The more strongly decomposed peat retains more water; it is, however, simultaneously less "spill proof". On the other hand, peat decomposed more strongly has a higher exchange capacity when referring to volume and can thus store more nutrients. The increased buffer capacity towards pH adjustments can also be positively assessed. The pH itself and the contents of soluble nutrients are not influenced by the degree of decomposition.

- What is the difference between block peat and milled peat?

-

Block peat refers to the machine extraction of peat blocks by white peat cutting machines. The peat blocks or sods must dry in the field for at least one year in order to reduce the moisture content from 90 % to about 40-60 %. In the factory, the peat blocks are crushed and sieved into various fractions.

Harvesting milled peat requires milling a few centimeters of the peat fields, which are leveled and drained beforehand. The loosened layer is turned repeatedly. The dry, loose peat is then pulled or shoved together into a small pile and afterwards vacuum harvesters collect and transport it to larger stockpiles. Although milled peat is cheaper to harvest than block peat, it generally has a larger amount of fine granulation.

- Which quality does terracult’s peat have?

-

The quality of high moor peat is influenced by many parameters. The origin and harvest methods play the largest role, but also the storage that is carried out after the harvest and processing is fundamentally responsible for the quality. Correspondingly, we distinguish between milled and block peat and a distinction is also made between A peat (for substrate production) and B peat (for potting soils). The latter is subject to less demanding criteria.

Self-heated peat is exempt from sales through Terracult International GmbH! The chemical qualities of pure peat are determined at its origin and are checked regularly according to the methods of terracult’s quality assurance.

- Are there alternatives to peat?

-

It is practically impossible to imagine commercial horticulture without peat. Peat-free cultivation using rock wool (Grodan), coco fiber or bark compost substrate only plays a subordinate role. On the other hand, peat-free or peat-reduced potting soils are available with different proportions of substrate compost, bark humus, clay, wood chaff, wood fibers, coco waste or similar materials.

- Will the last remaining moors be destroyed by harvesting peat?

-

This question was examined in September 2008 in a study done by the European Peat and Growing Media Association (EPAGMA) titled "Socio-economic impact of the peat and growing media industry on horticulture in the EU". According to the study, there are 4 million square kilometers of bog areas worldwide. Of this, peat is harvested for industrial purposes on 2,000 square kilometers; this corresponds to about 0.05% of the total area worldwide.

- Where does the peat come from?

-

Terracult obtains its peat from different selected plants in the Baltic States (Estonia, Latvia, Lithuania), Belarus and the Ukraine.

- How is the quality of terracult’s peat and substrates guaranteed?

-

Terracult has defined uniform guidelines for the quality assurance of its peat products and peat substrates in cooperation with the independent consultancy firm Horticon. The guidelines correspond with today’s general guidelines of the Gütegemeinschaft für Substrate und Torf (Quality Assurance Association Growing Media for Plant Cultivation).

For each of our products we have a main data sheet that identifies the characteristics, the mixture and the quality criteria. The data of the respective batch is recorded onto a measurement data sheet. By comparing these measurements with the values next to them (the tolerance range) mistakes or deviations can be recognized immediately. For every batch, the pH, EC value, granulation and dimensional weight are measured and documented in the laboratory. The measurement of the fraction, as is the case for peat products, is an important indicator for the physical quality characteristics.

In addition to controlling the quality of the harvest and its weather-induced changes, the respective batch is inspected, particularly for compliance with the norms (sub-grain and over-grain). In order to be able to analyze a possible defect or mistake at a later date, when the product is already with the customer, every packing unit gets a corresponding declaration. In connection with the delivery note, the manufacturer as well as the delivery and production dates can therefore be found out easily at any time.

- What do bogs and peat have to do with the climate?

-

Concerning this topic, there is a 2009 brochure from DGMT, the German Peat Society. It can be found as a PDF file in our download section.

- What does the degree of decomposition for peat (H) mean?

-

The degree of decomposition for peat can be understood as the relative proportion of humification products of the entire peat substance. The definition continues with a scale of one to ten, the von Post humification method. One represents not decomposed material with visible plant structures and ten represents completely decomposed material with no longer recognizable structures.

In the topmost strata of the bog, the mosses still have well recognizable structures. Sphagnum moss, also called pale moss due to its light color, has a faint, whitish appearance. The lower the stratum is, the darker the color gets. White peat is found in the topmost layers, brown peat in the transition layers and black peat in the oldest, undermost, highly decomposed layers of a bog.

- Which moisture content does peat normally have?

-

Normally, Terracult’s white peat has a moisture content of 50-60 %. The quality suffers when the moisture content is lower; when the packaging is pressed, volume losses can arise and re-wetting can be difficult. Sometimes the moisture content reaches more than 60 %, mostly when the harvest conditions are not ideal. This then can limit the maximum amount of loading per truck.

One can generally say that the peat’s high water holding capacity is unsurpassed and that it positively influences plant growth when there is a high amount of air at the same time.

- What is unique about peat?

-

Modern, efficient commercial horticulture is not conceivable without peat substrates that have exactly defined qualities and requirement profiles.

A high water holding capacity and a simultaneously high amount of air promotes plant growth. Peat has a stable structure and due to the raw material’s low amount of nutrients and low pH, it is possible to produce optimal mixtures with suitable additives for all sorts of plant species. Peat as an essential basis of substrates therefore forms the foundation for the cultivation and propagation of plants.

Professional substrates with a peat basis have become just as important for production as seeds, fertilizers or young plants.

The essential features of peat substrates include the following:

- Stable composition, low dimensional weight

- Permanent availability

- Guaranteed structure

- Structural stability over long periods of time

- High pore volume

- High water and air capacity

- High capillarity

- Good absorbing capacity

- Exact range of fractions

- Free of pollutants and diseases

- Rather inactive against microbes

- Favorable pH buffering against pH adjustment

- Low nutrient content

- Fast re-wetting after desiccation

With additives such as fertilizer, calcium carbonate, clay, sand, perlite, coco fiber, humus, etc. the already good physical and chemical qualities of the raw material peat get optimized in the substrates corresponding to the requirements of the cultivated plants.

- What is coconut?

-

Coconut is the fruit of the tropical coconut palm (Cocos nucifera). The tissue around the actual fruit (mesocarp) consists of fibers and fine material.

In the past, only the fiber was processed into ropes, mats, carpets and other products, and the fine material was brought to landfills as waste. Today, after removing the coconut, the thick shell (husk) is increasingly being used as a substrate medium in horticulture. Depending on the use, we distinguish between coir (fine material, also known as "coco peat"), fibers and cut coconut pieces (chips).

- Where does coconut originate?

-

Coconut palms grow in tropical areas of the world and are now cultivated as a valuable crop in large plantations. The main producing countries are Indonesia, the Philippines and India (about 80 % of the world's harvest).

- How is coconut obtained?

-

The coconut fruit is split, and the valuable coconut is removed. The shell (husk) is crushed in a fast-rotating grinder. The valuable fibers are separated from the coir. Large coconut pieces are obtained by cutting or crushing.

- Physical properties of coir and sphagnum peat

-

Dry Weight Water Holding Capacity Air Capacity Coir 80 - 90 g/L 40 - 60 % 20 - 30 % Sphagnum Peat 80 - 150 g/L 50 - 70 % 25 - 45 % - Chemical properties of coir and sphagnum peat

-

pH EC value N P K Coir 5,0 - 5,5 < 1,0 < 5 mg/L < 5 mg/L < 40 mg/L Sphagnum Peat 3,0 - 3,5 < 0,5 < 50 mg/L < 15 mg/L < 20 mg/L - Wettability of coconut

-

Coconut has a hydrophilic character. This means that extremely dry coconut absorbs water very quickly.

- Coir

-

Coir is supplied commercially in the sieve fractions 0-4, 0-6 and 0-12 mm.

- Coconut fiber

-

Coconut fiber is supplied commercially in the sieve fractions 0-10, 0-20 and 0-30 mm.

- Coconut chips

-

Coconut chips are supplied commercially in the fractions 0-12 and 0-25 mm.

- Why is coconut "washed"?

-

The crushed materials in coir, coconut fiber or chips are washed on smaller, flat piles in order to wash out the high potash values embedded in the fruit. In the past, the coconut husks were soaked in sea water or lagoons in order to better detach the fiber. With this method, the high salt values (sodium, chloride) had to be washed out particularly intensly with fresh water. Drying of the material takes place on dry fields; for coconut substrates in 200 L bales or 6,000 m³ big bales, the material is dried to a water content of about 45 %.

Highly compressed coconut blocks to be used as coir, chips or fibers are dried back to a water content of 18 %.

- Why is coconut "buffered"?

-

After washing and if requested by the customer, the absorption of calcium and magnesium can be improved by the addition ("buffering") of calcium nitrate (Ca(NO3)2). Washed and additionally "buffered" coconut material is a particularly valuable material for high-quality substrates in the propagation and further cultivation of plants.

- How long is the delivery period?

-

Depending on the goods and the amount, it takes approx. 7-14 days for delivery after the order has been received. In individual cases, delivery times may take longer. For container deliveries, the delivery period is dependent on the transit times of the containers (Europe: approx. 4 weeks, Asia: approx. 6 weeks).

We inform our customers about the expected delivery date in the context of the order confirmation.

- Do I need a forklift for unloading?

-

Yes, a forklift is necessary for unloading since the big bales weigh approx. 1,000 kg to 1,400 kg (with clay), or 800 kg to 1,000 kg (with clay) for bagged goods.

- How is the product delivered?

-

In general, peat/substrate is delivered with 13.60 m semi-trailers or in exceptions with refrigerated trucks (without forklift help).

For deliveries outside the EU, 40' HC (high cube) containers are used.

All large container ports are generally possible as a final destination.

You want to add an interesting question?

Do you have an interesting question and an appropriate response to topics related to peat and substrates? If so, please do not hesitate to send us an email.